Fin Tube Series Condenser Tubes with Aluminum Finned, Base Tube of Copper Alloy, Stainless Steel, Carbon Steel, Copper

Overview Finned tube A finned tube is a kind of heat exchange element. It is a kind of heat exchanger tube to improve th

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Performance | Pressure Resistant, Temperature Resistant, Corrosion Resistant |

| Material | Customized |

| Full Customization | Customized |

| Transport Package | Customized |

| Specification | Customized |

| Trademark | BANGWIN |

| Origin | China |

| HS Code | 1601001010 |

| Production Capacity | 50000pieces/Years |

Product Description

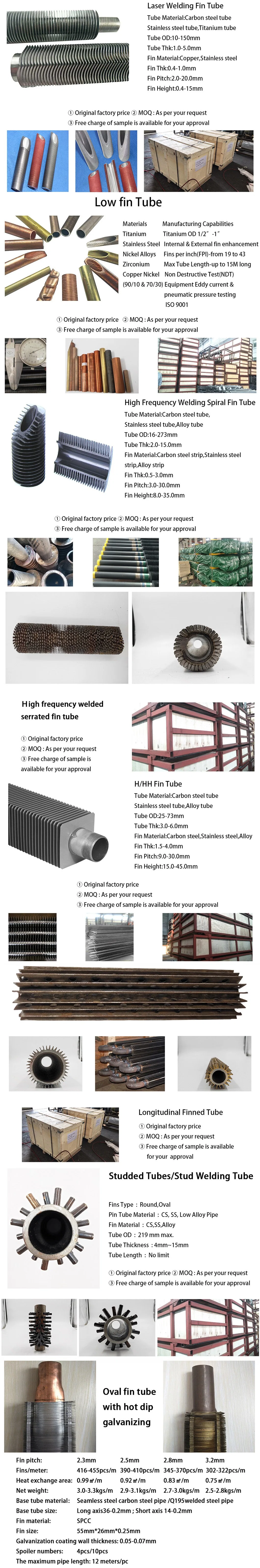

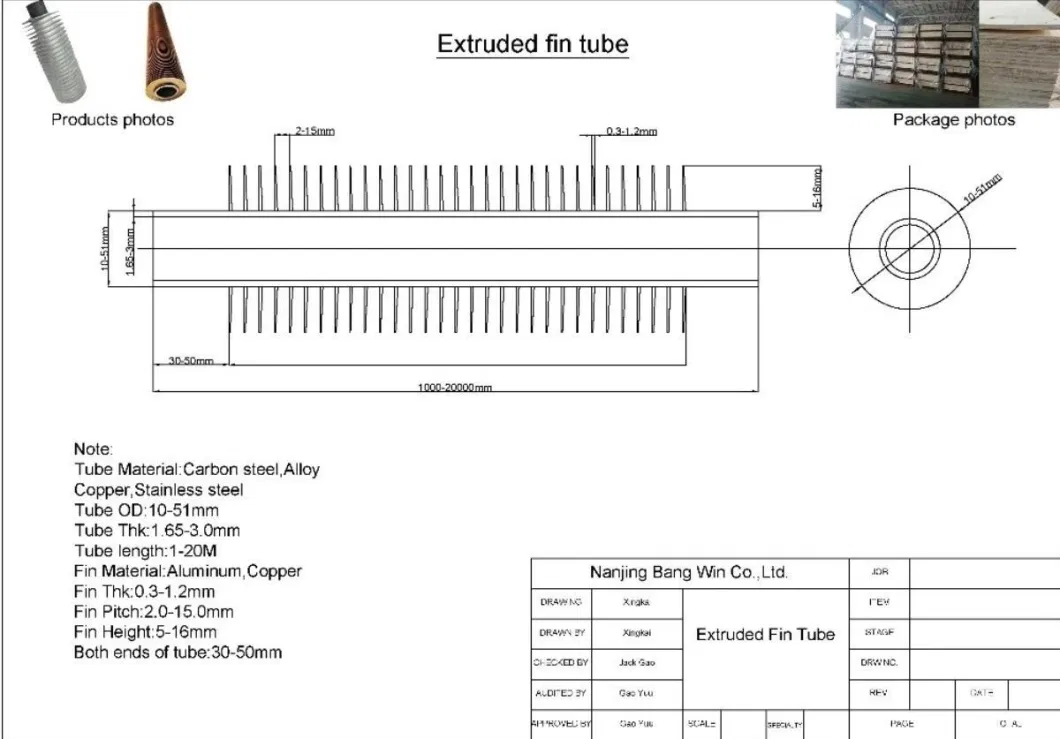

Finned tube

A finned tube is a kind of heat exchange element. It is a kind of heat exchanger tube to improve the heat transfer efficiency, usually by adding fins on the surface of the heat exchanger tube to increase the external surface area (or internal surface area) of the heat exchanger tube, so as to achieve the purpose of improving the heat transfer efficiency.

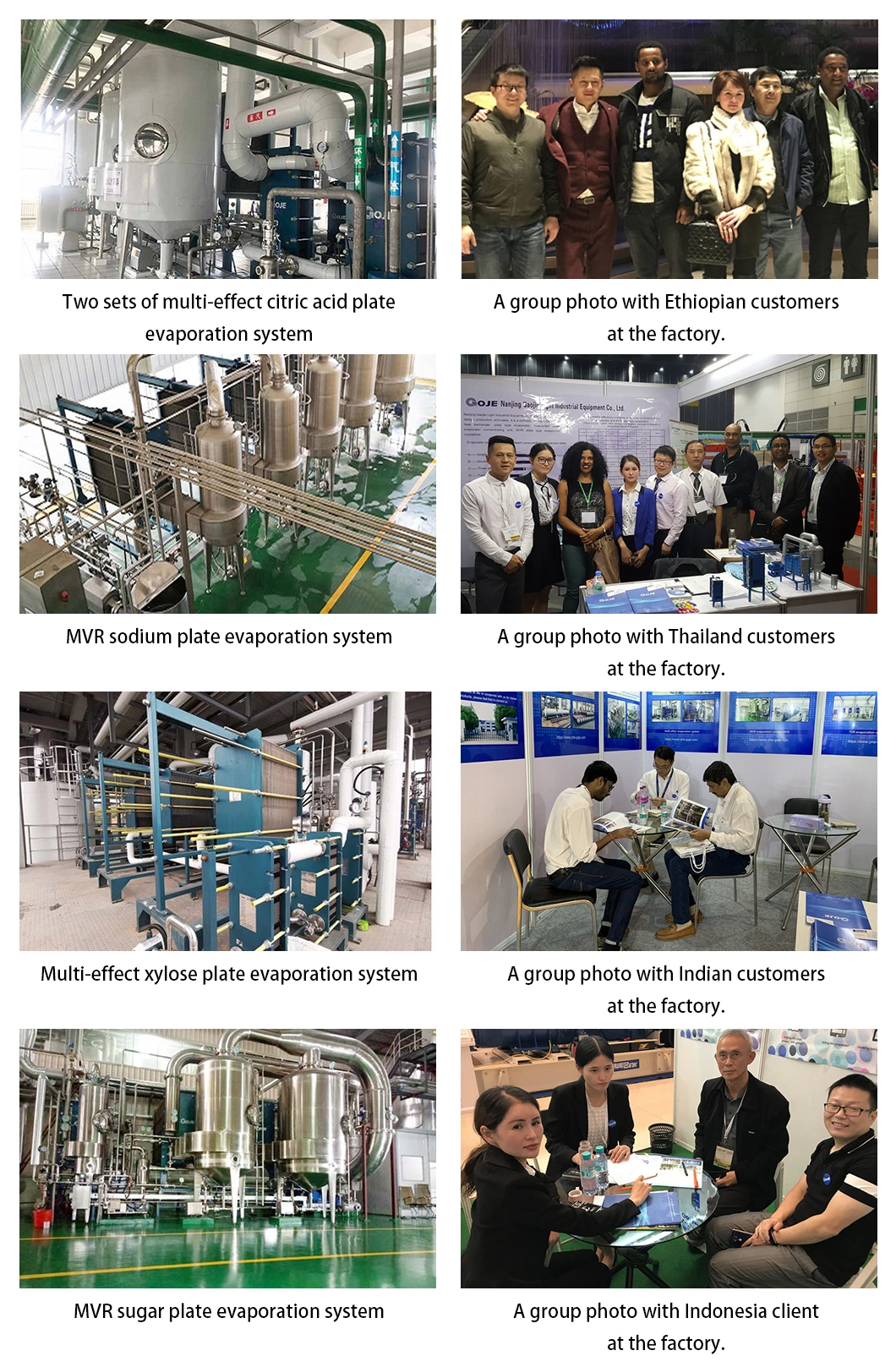

Professional Plate Heat Exchanger Factory With 20 years Experience ONE-STOP Heating Transfer Solution For You Design different plate heat exchanger for your usage (Metallurgy, food, petrochemical, pharmaceutical, beverage, wastewater, refrigeration etc..)

Nanjing Bangwei Import & Export Trade Co., Ltd. is a professional manufacturer of various finned tubes and heat exchenger integrating R&D, design, production and sales.The produced are mainly used in petrochemical, electric power, paper making, building heating, mineral and other industries, such as air heater, food industry plant protein powder, starch and other air heater spray drying system.The company now has a professional technical innovation team, and professional after-sales personnel.The company's production plant covers an area of about 18,000 square meters, with many professional advanced CNC and automatic production equipment, and has obtained a number of professional certificates and patents.The company has a professional foreign trade team, and has trade cooperation with various regions Some global partners have made site visits to the production plant and they are very satisfied with the results of the visits and have established a long-term strategic cooperation relationship with our company.

Customized product design drawings for customers in Thailand.One-on-one design matching by professional designers

Tailor-made for customers

Customized product design drawings for Turkish customer for washing machine manufacturing plant TOLONProfessional designers for one-on-one design matchmaking

Customer tour of the factory and cooperation matters

| 1 | Inquiry-Professional quotation, or send inquiry item more details ,we start contact more details |

| 2 | Confirm the price, lead time, payment term etc |

| 3 | Our sales send the Proforma Invoice with our seal, or you order online to us |

| 4 | Customer make the payment for deposit and send us Bank receipt. |

| 5 | Initial Production Stage-Inform the clients that we have got the payment,And will make the samples according to your request, send you photos or Samples to get your approval. After approval, we inform that we will arrange the production & inform the estimated time. |

| 6 | Middle Production-send photos to show the production line which you can see your products . Confirm the estimated delivery time again. |

| 7 | End Production-Mass production products photos and samples will send to you for approval. You can also arrange the third party Inspection |

| 8 | Clients make payment for balance and Ship goods , Inform the tracking number and check the status for clients |

| 9 | Order can be say "finish" when you receive the goods and satisfy with them |

| 10 | Feedback to our about Quality , Service, Market Feedback & Suggestion. And we can do better |